- Home

- /

- Product

- /

- Foundation Tools

- /

- Roller Bit

- /

- MH-3C

Replaceable Type Roller Bit

MH-3C

MH-3C series is designed for contractors requiring flexibility and convenience in bored piling operations. It utilizes a dual assurance design combining mechanical bolt connections with welding, ensuring the reliability of connections while allowing for the onsite replacement of roller bits.

The roller bits is derived from the advanced FIRMTECH Pro model MH-3, inheriting its advantages and further featuring convenient replacement and precise welding positioning capabilities.

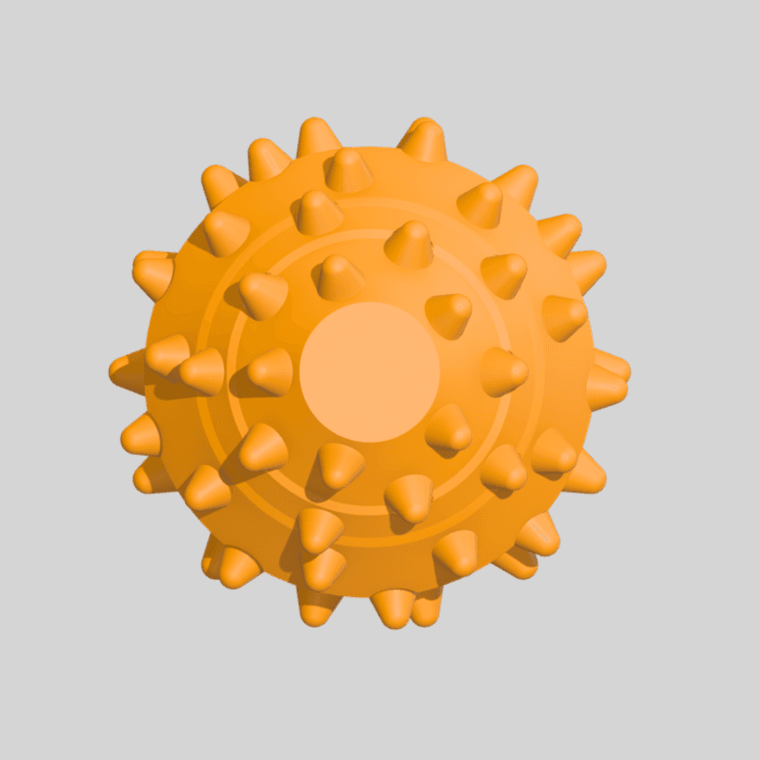

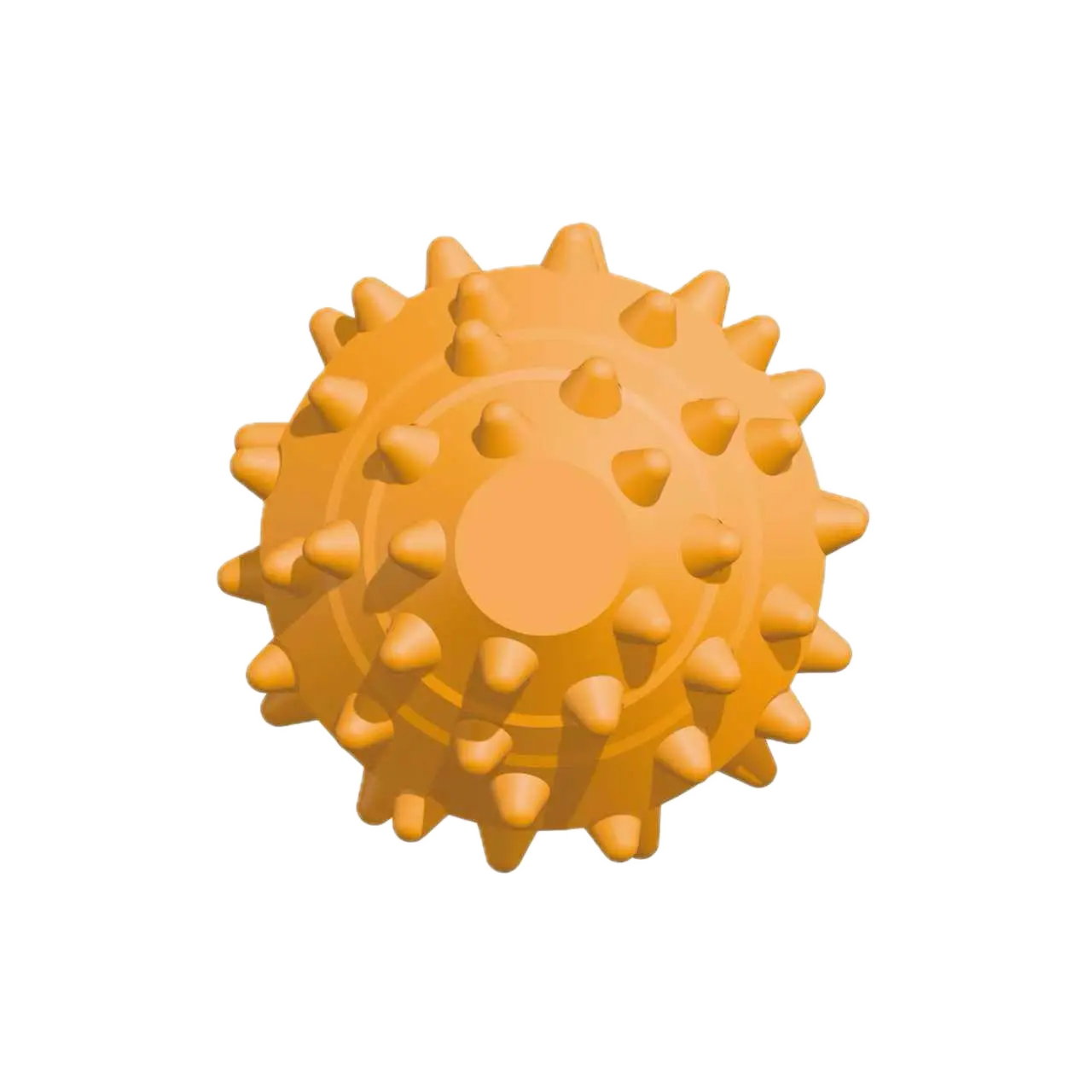

3rd Generation Cone

- Full Covered 3rd Generation

- Inserts Qty: Maximized 52 pcs

- OD: 139 mm

- Feature: Fully covered insert, no blind spot

- Performance: Maximum duration & penetration rate

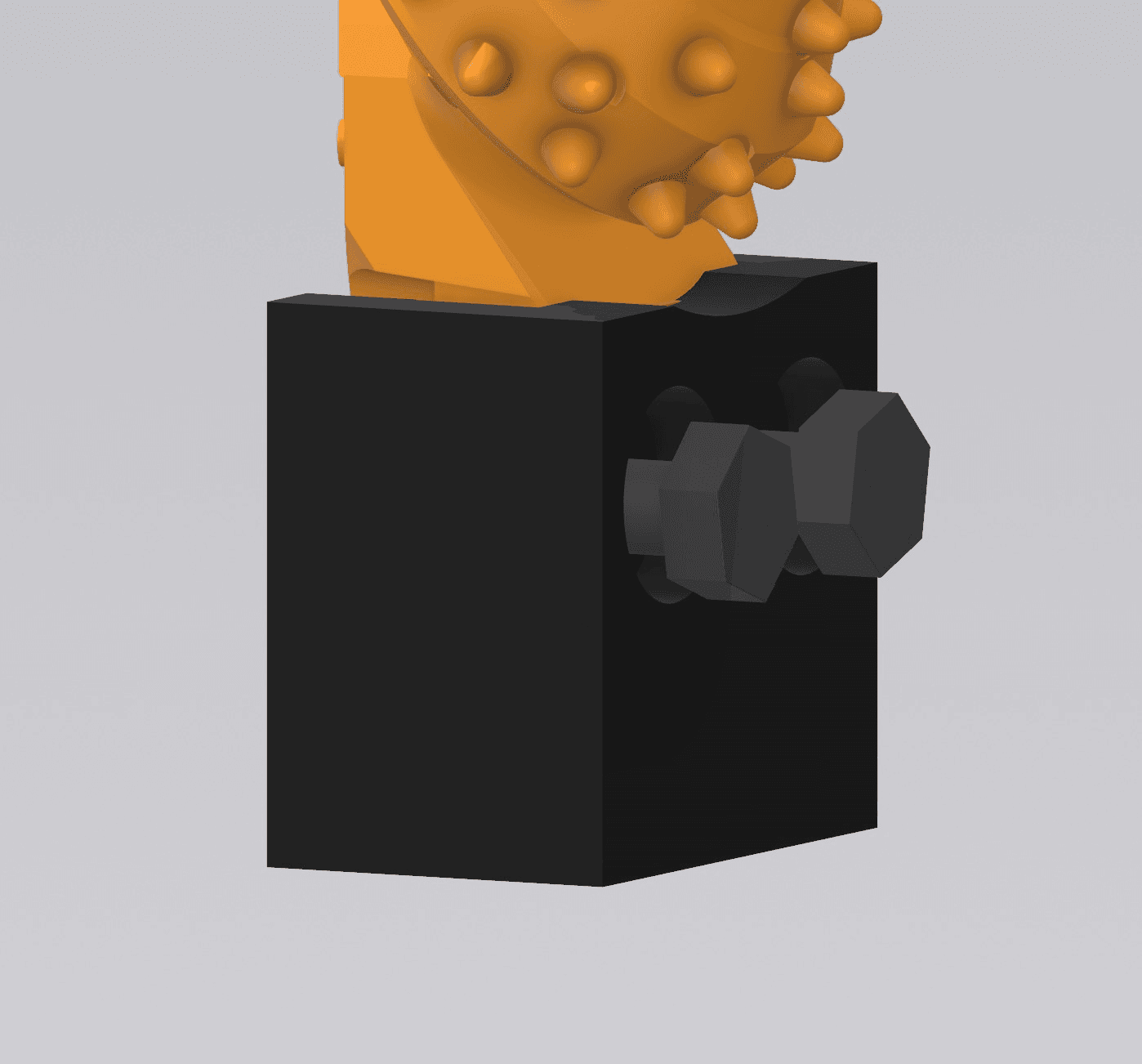

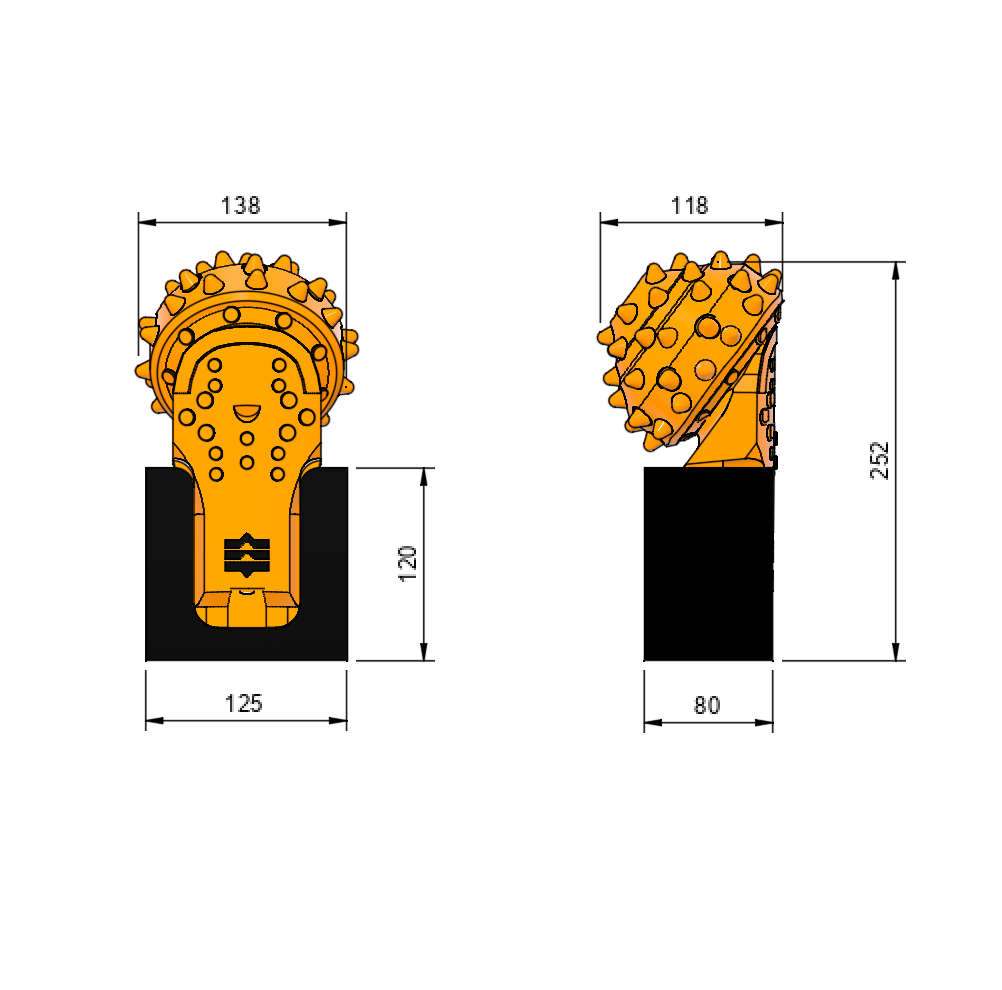

Slot & Bolts Connection

- Base slot with dual-bolt connection

- Threaded Rollers: Ensures stable connection strength over time

- Durability: Maintains high strength, resisting wear and tear

- Easy Maintenance: Reduced contact area for easier roller replacement

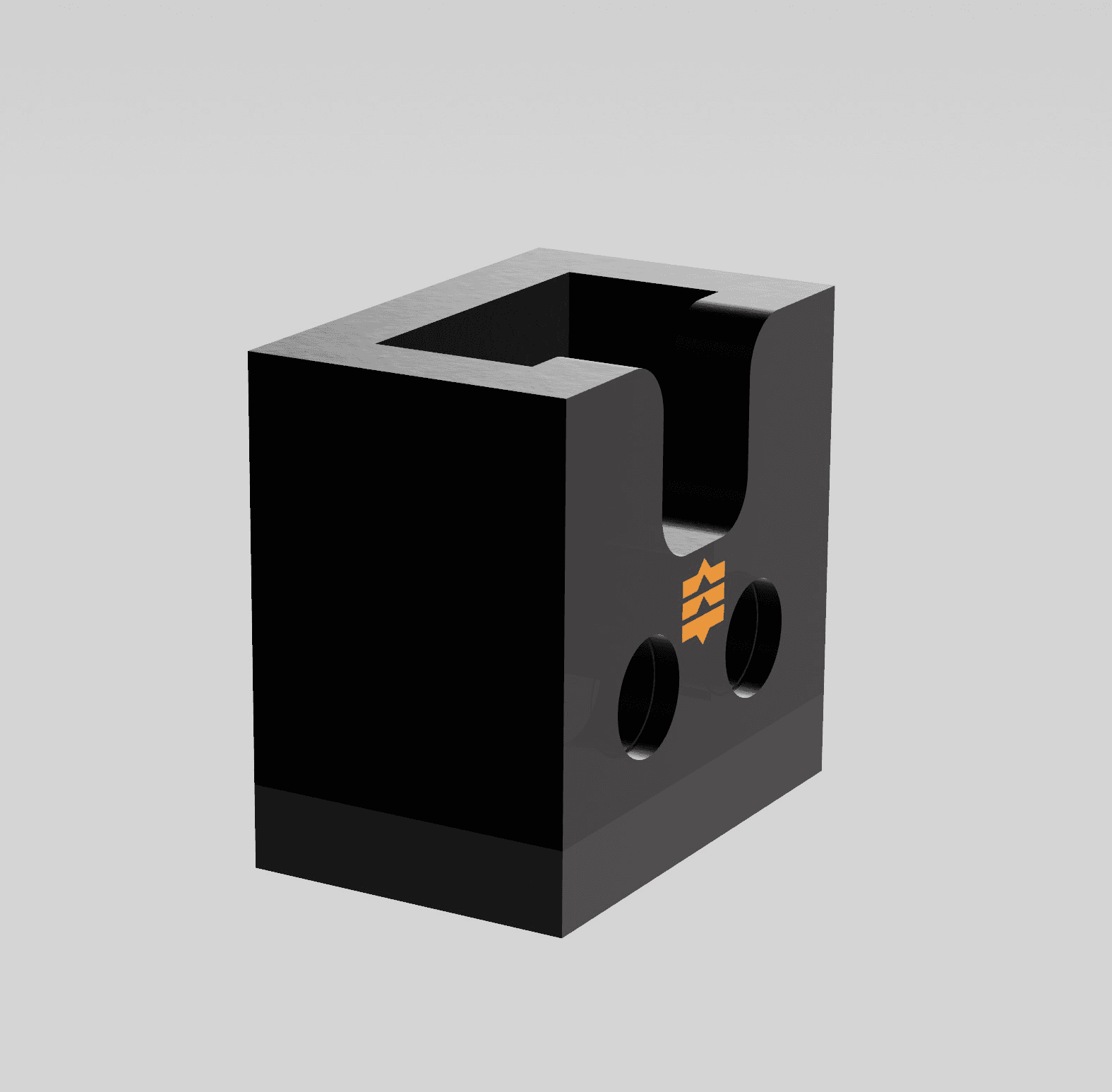

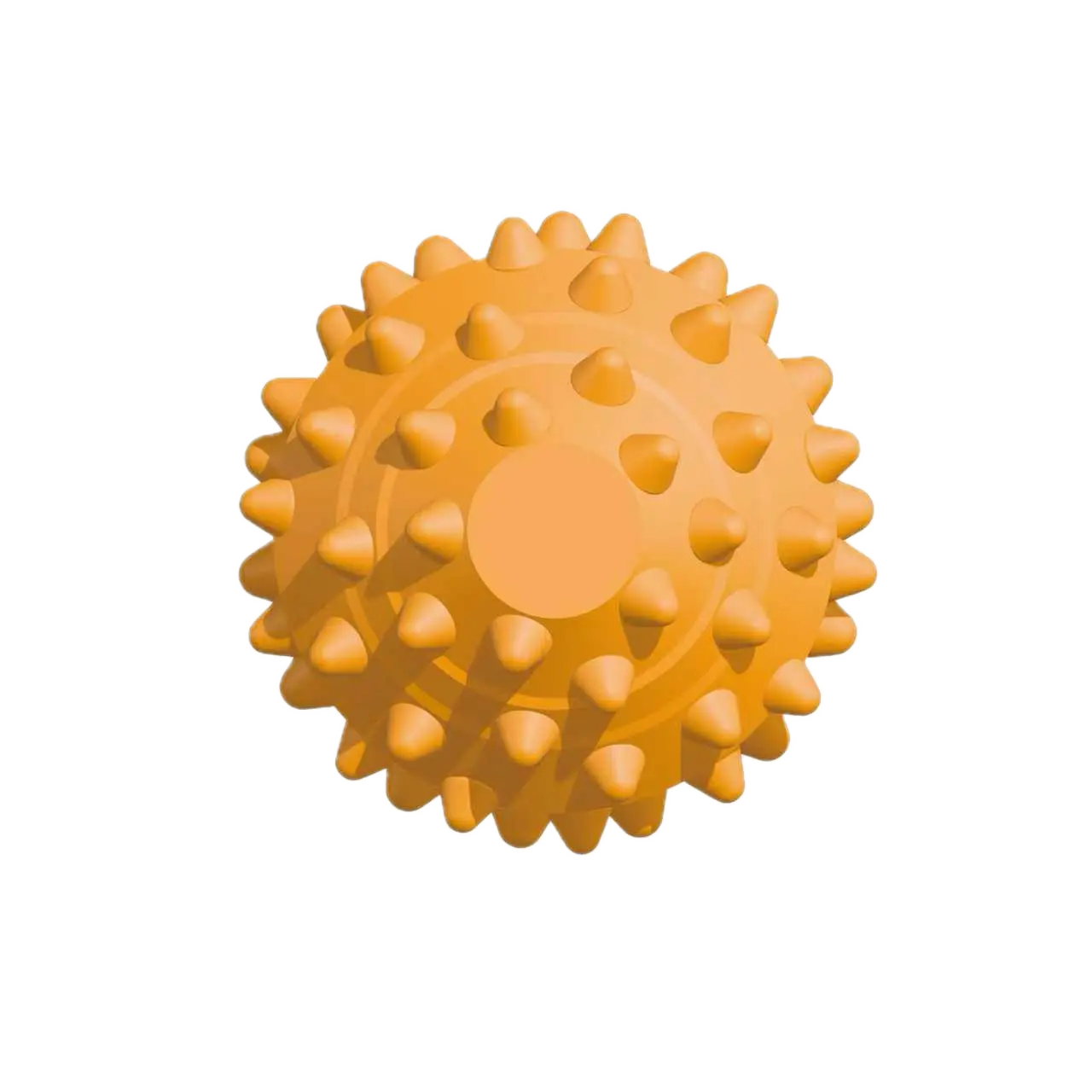

3rd Generation Cone

- Spec:125mm*80mm*120mm

- Increased holder thickness for enhanced durability

- Advantages:

- Minimizes the impact of welding heat on the bearing system.

- Accurate positioning, quick replacement.

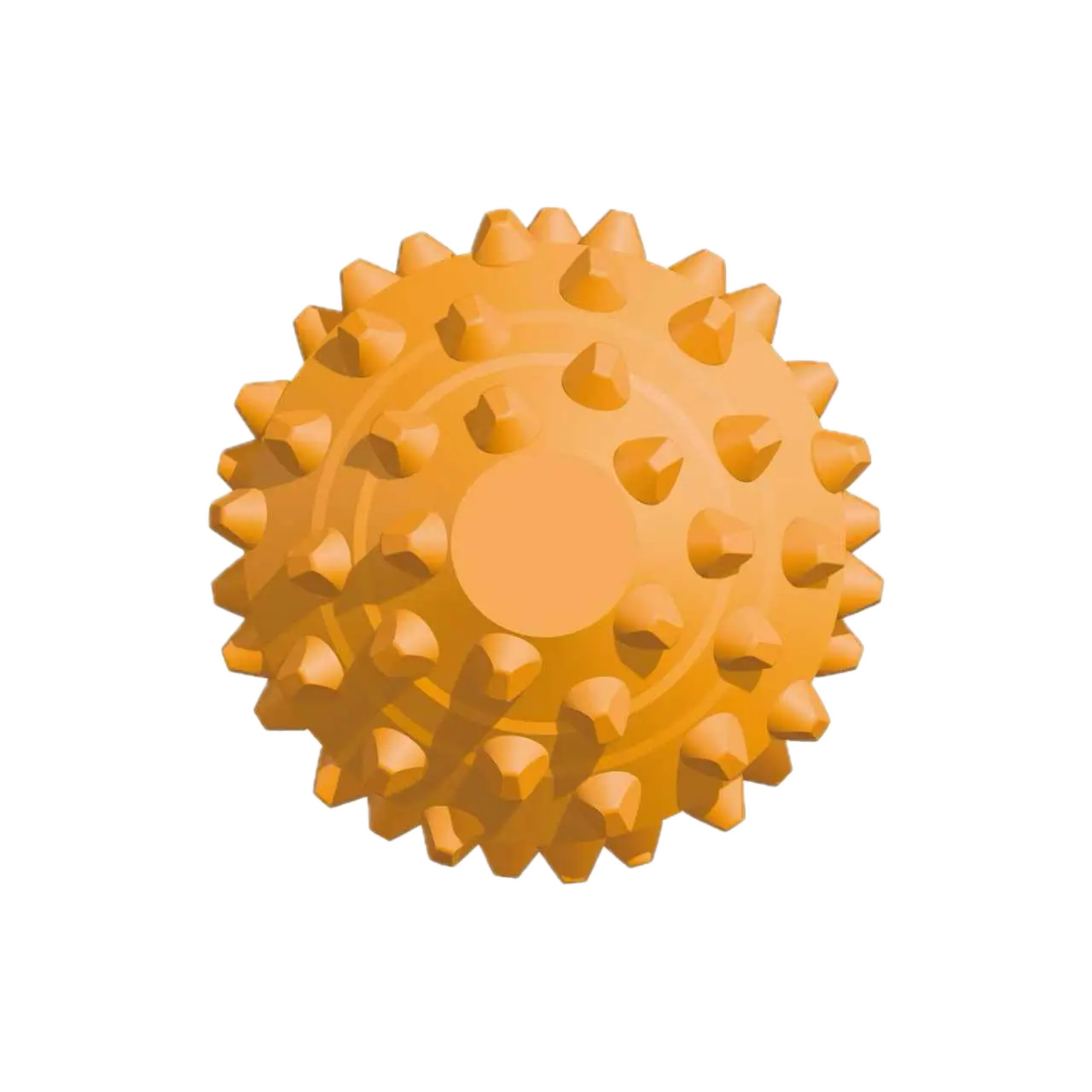

Perfect Inserts for Every Rock Type

Engineered for All Rock Conditions—Tailored Solutions for Your Unique Project

Chisel

60-110MPa

Conical

100-180MPa

Spherical

130-280MPa

Spec.

MH-3C

Current spec. similar to 8.5″, we also have 12.5″ roller cutter, which could customize as per request

Additional Support

Select Roller Bit

Selecting the appropriate type and quality based on the geological formation is crucial for optimizing drilling efficiency

Improve Tool Design

A well-designed core barrel enhances debris removal, significantly improving drilling efficiency

Welding Instruction

Correct roller bit placement and welding accuracy are vital for achieving the desired drilling results.

Operation Tips

Proper control of drilling weight and rotating speed directly impacts penetration rates and roller bit wear

DRILLNOVA specializes in high-performance foundation drilling tools.

Reduce downtime, boost drilling efficiency.

👉 Download our catalog to find Roller Bits built for reliable performance.