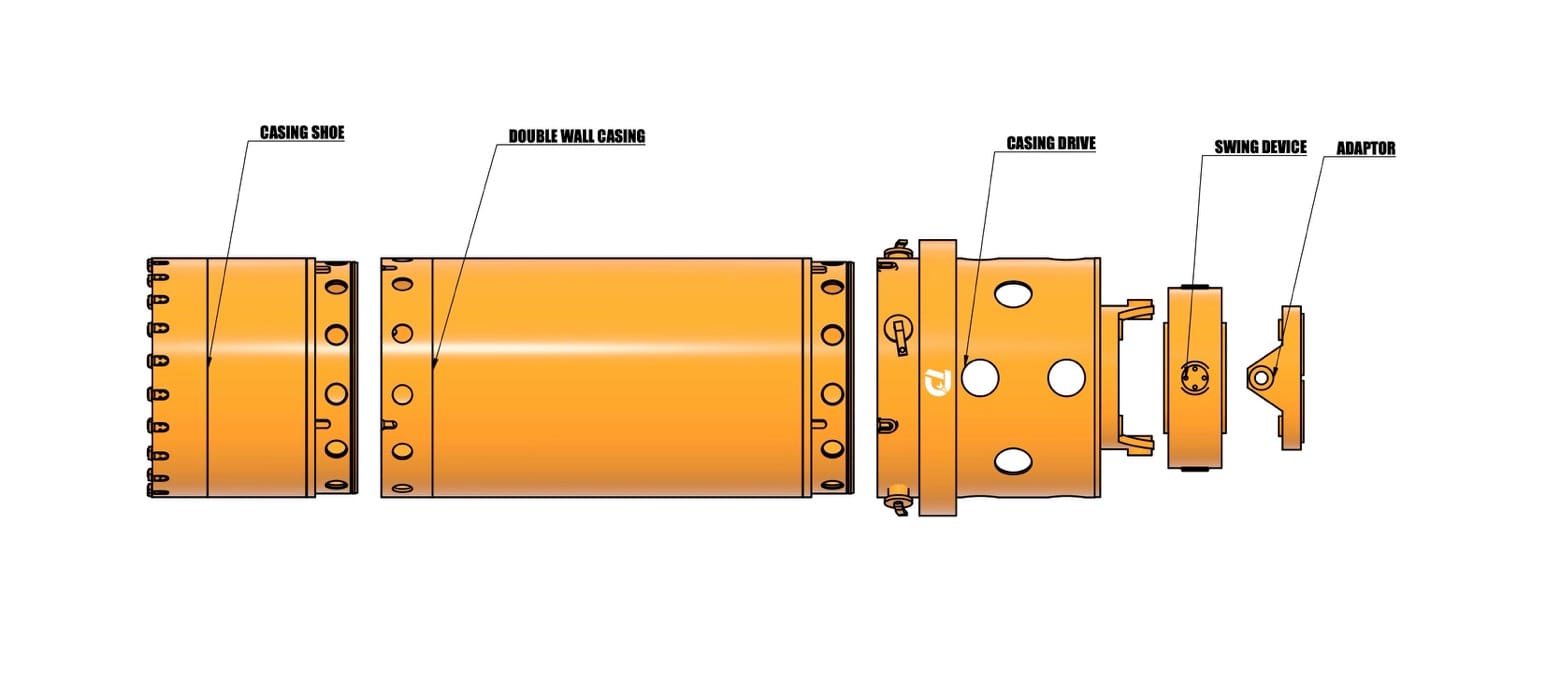

Drillnova’s Double Wall Casing System is designed for high-performance rotary drilling in challenging soil conditions. Engineered with durability and precision in mind, our system includes:

- Double Wall Drill Casing

- Single Wall Drill Casing

- Casing Shoes

- Casing Joint

- Casing Adaptor

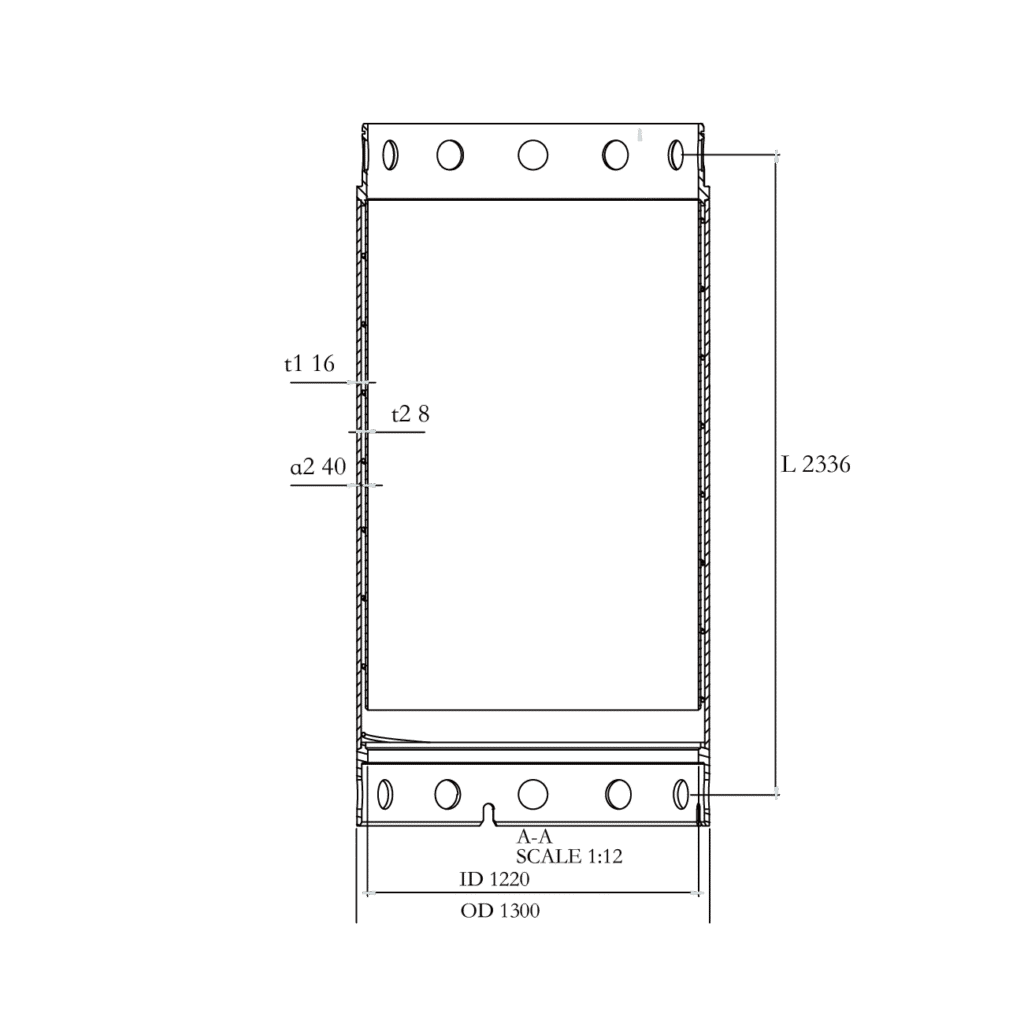

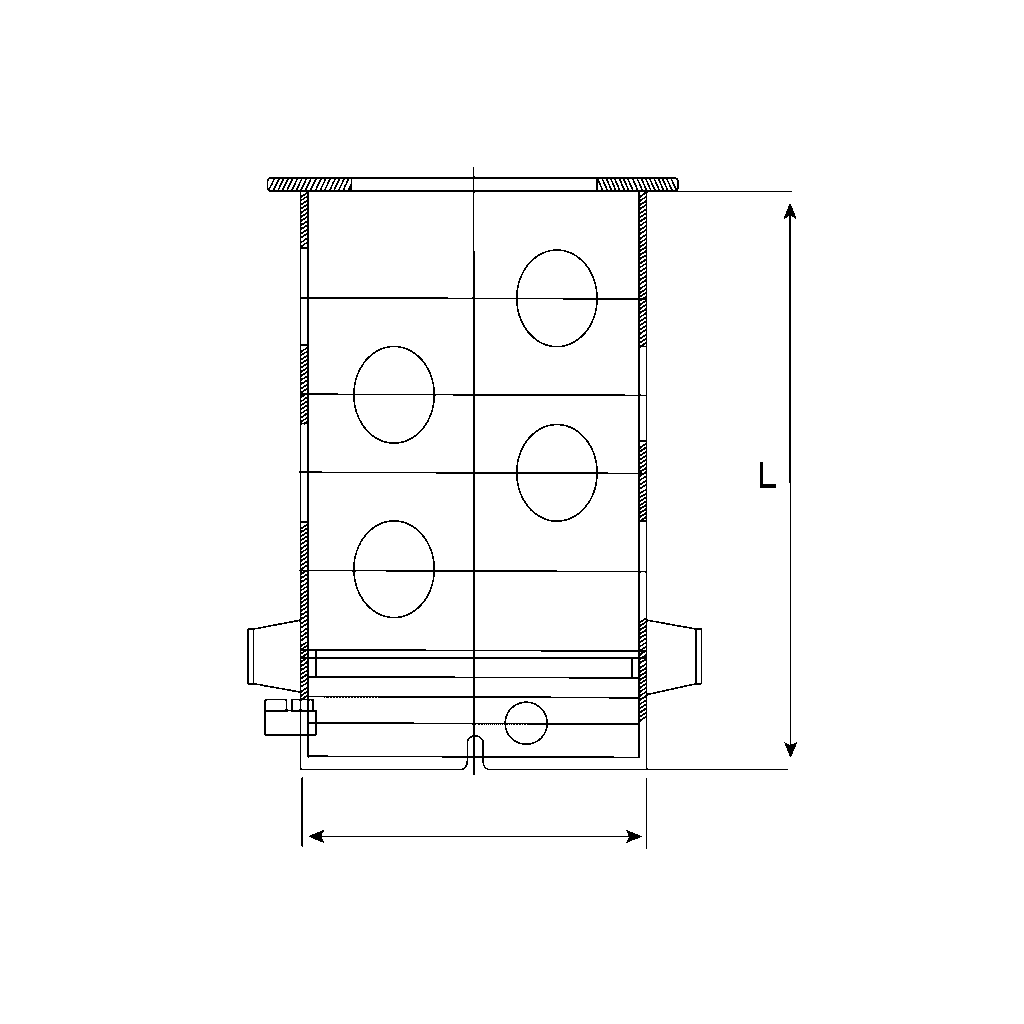

DOUBLE WALL SEGMENTAL CASING

Double-wall casings consist of two layers of steel, with a gap & filler material between them,

providing higher strength and torsion resistance.

Advantages:

- High Strength: The double-wall structure makes these casings more durable, allowing them to perform well under high torque and in difficult geological conditions.

- Durability: Double-wall casings are less prone to deformation or damage in hard rock formations or gravel layers, offering longer service life.

- Better Torsion Resistance: They can transmit the rotary torque more effectively, ensuring stable performance during drilling.

Application:

Ideal for complex geological conditions, such as hard rock formations or gravel layers, and deep drilling operations that require high strength and durability.

Parameters

| DIAMETER | LENGTH L (WEIGHT) | CASING WALL THICKNESS | BOLTS | |||||||

| D1/D2 (mm) | 1m (kg) | 2m (kg) | 3m (kg) | 4m (kg) | 5m (kg) | 6m (kg) | t1 (mm) | t2 (mm) | Total Thickness a2 (mm) | Bolt Qty (nos) |

| 620/540 | 403 | 739 | 1074 | 1411 | 1747 | 2081 | 12 | 8 | 40 | 8 |

| 750/670 | 492 | 902 | 1311 | 1722 | 2131 | 2540 | 12 | 8 | 40 | 10 |

| 880/800 | 585 | 1069 | 1552 | 2036 | 2520 | 3005 | 12 | 8 | 40 | 10 |

| 1000/920 | 669 | 1221 | 1773 | 2328 | 2877 | 3429 | 12 | 8 | 40 | 10 |

| 1180/1100 | 844 | 1580 | 2316 | 3052 | 3787 | 4522 | 16 | 8 | 40 | 12 |

| 1200/1120 | 872 | 1620 | 2370 | 3120 | 3870 | 4620 | 16 | 8 | 40 | 12 |

| 1300/1220 | 933 | 1246 | 2558 | 3372 | 4184 | 4996 | 16 | 8 | 40 | 12 |

| 1500/1400 | 1433 | 2628 | 3817 | 5009 | 6210 | 7393 | 20 | 10 | 50 | 12 |

| 1800/1700 | 1730 | 3166 | 4602 | 6038 | 7474 | 8910 | 20 | 10 | 50 | 12 |

| 2000/1880 | 2450 | 4280 | 6110 | 7940 | 9770 | 11600 | 20 | 10 | 50 | 12 |

| 2200/2080 | 2700 | 4720 | 6740 | 8760 | 10780 | 12800 | 20 | 15 | 60 | 12 |

| 2500/2380 | 2960 | 5240 | 7520 | 9800 | 12080 | 14360 | 20 | 15 | 60 | 16 |

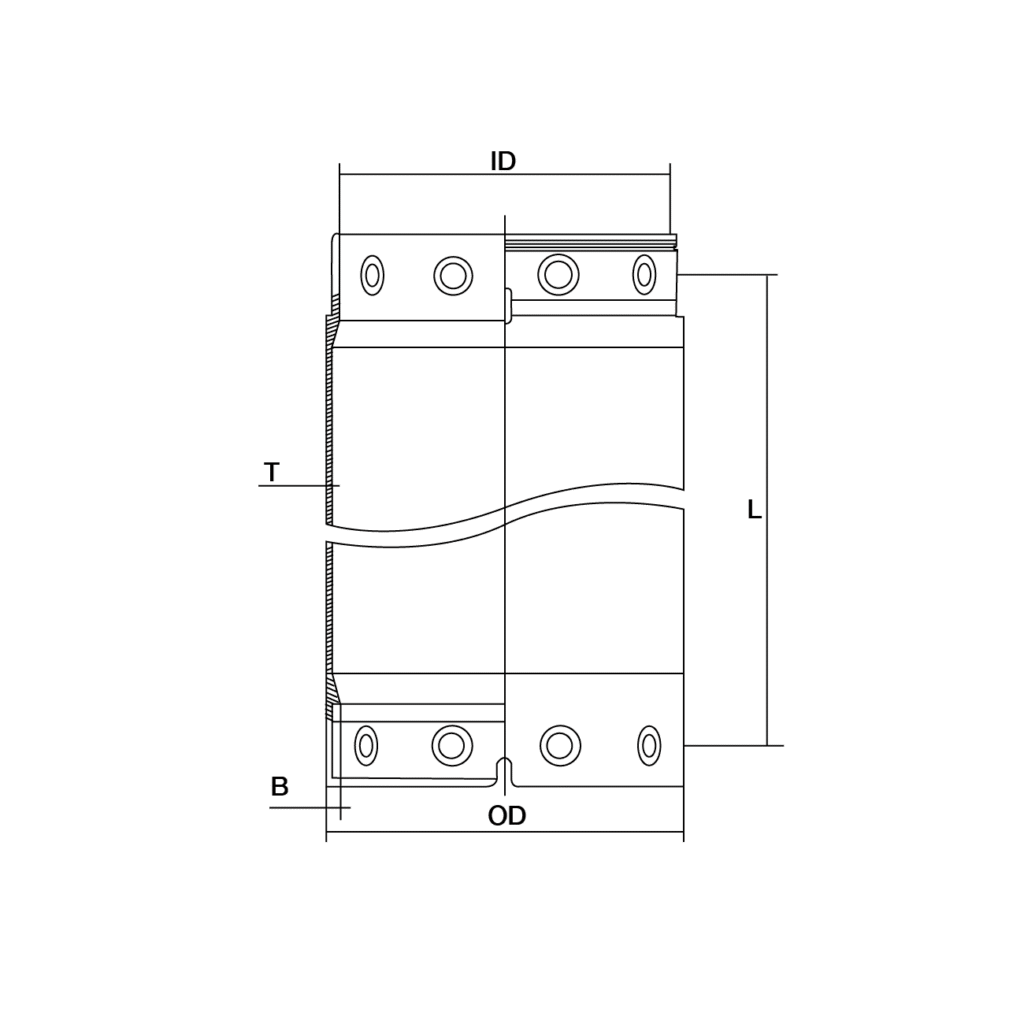

SINGLE WALL SEGMENTAL CASING

Single-wall casings are made from a single layer of steel and are typically used in simpler geological conditions.

Advantages:

- Lightweight: Due to their single-layer structure, single- wall casings are lighter and suitable for shallow or soft soil drilling operations.

- Lower Cost: They are less expensive to produce and use less material, making them a budget-friendly option for certain projects.

Application:

Suitable for projects in soft soil or shallow drilling, such as sandy or clay soils, where the geological conditions are relatively straightforward.

Parameters

| DIAMETER | LENGTH L (WEIGHT) | CASING WALL THICKNESS | BOLTS | ||||||

| D1/D2 (mm) | 1m (kg) | 2m (kg) | 3m (kg) | 4m (kg) | 5m (kg) | 6m (kg) | T (mm) | B (mm) | Bolt Qty (nos) |

| 1300/1220 | 845 | 1475 | 2105 | 2735 | 3365 | 3995 | 20 | 40 | 12 |

| 1500/1400 | 1310 | 2220 | 3130 | 4040 | 4950 | 5860 | 25 | 50 | 12 |

| 1800/1700 | 1580 | 2675 | 3770 | 4865 | 5960 | 7055 | 25 | 50 | 12 |

| 2000/1880 | 2140 | 3355 | 4570 | 5785 | 7000 | 8215 | 25 | 60 | 12 |

| 2200/2080 | 2350 | 3690 | 5030 | 6370 | 7710 | 9050 | 25 | 60 | 12 |

| 2500/2380 | 2575 | 4100 | 5625 | 7150 | 8675 | 10200 | 25 | 60 | 16 |

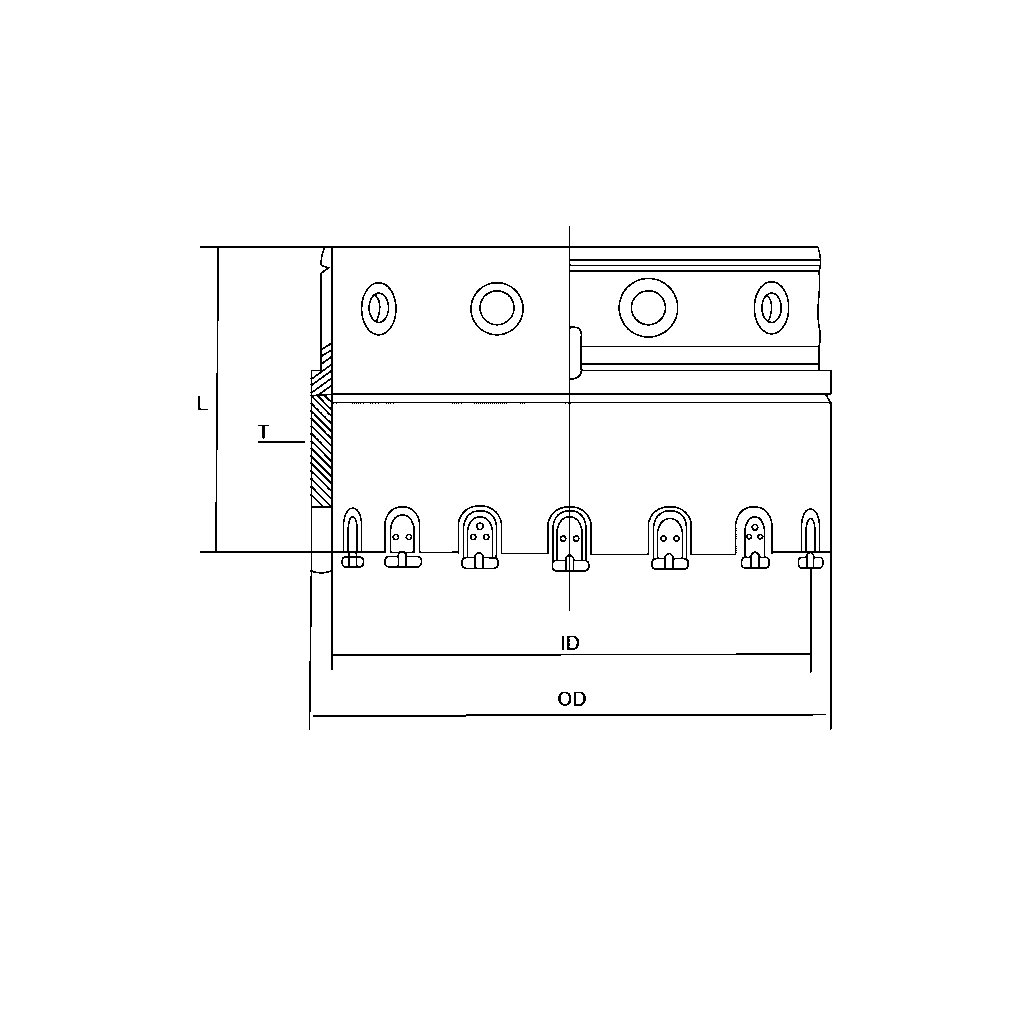

CASING SHOE

Single-wall casings are made from a single layer of steel and are typically used in simpler geological conditions.

Advantages:

Hardened steel edge for cutting performance

-

Extended service life under tough conditions

-

Essential support for bored pile casing systems

Application:

-

Foundation projects in mixed ground layers

-

Bored pile casing for bridges and infrastructure

-

Rotary drilling works requiring stable casing installation

Parameters

| Diameter | 620 (mm) | 750 (mm) | 880 (mm) | 1000 (mm) | 1180 (mm) | 1300 (mm) | 1500 (mm) |

| Tooth Quantity | 14 | 16 | 18 | 18 | 20 | 24 | 30 |

| Weight (kg) | 309 | 374 | 439 | 500 | 589 | 653 | 955 |

Casing Joint & Drive

Advantages:

-

Strong and reliable connection between casing tubes

-

Quick installation and disassembly

-

Reduced downtime during piling operations

Application:

-

Deep bored pile foundations

-

Rotary drilling casing systems for infrastructure

-

Projects requiring frequent casing assembly and removal

Casing System Shipment –

Reliable Supply for Global Projects

FAQ...

What is a casing system in rotary drilling?

What is a casing tube, and why is it important in pile foundation?

What is the difference between double wall casing and single wall casing?

What is the function of a casing shoe?

How do casing connectors work in a casing system?

Can casing systems be customized for special projects?

Are casing systems reusable?

How does the choice of casing system affect project cost?

DRILLNOVA specializes in high-performance piling drilling tools.

Reduce downtime, boost drilling efficiency.

Download our catalog to find Casings built for reliable performance.