Struggling to choose between PDC and Tricone bits? The answer depends on your project’s needs. Let’s explore how design differences impact drilling outcomes.

If the formation of your project is mainly soft or medium hard, it is recommended to choose a PDC drill bit because it provides higher efficiency and longer service life. If you are facing a harder rock or gravel layer, a three-cone drill bit may be more suitable.

Now, let’s dive deeper into how design and application scenarios influence your choice.

How Bit Design Affects Drilling Speed and Efficiency in HDD Projects?

Different designs create unique drilling behaviors. The wrong choice wastes time and money. Here’s how geometry and materials matter.

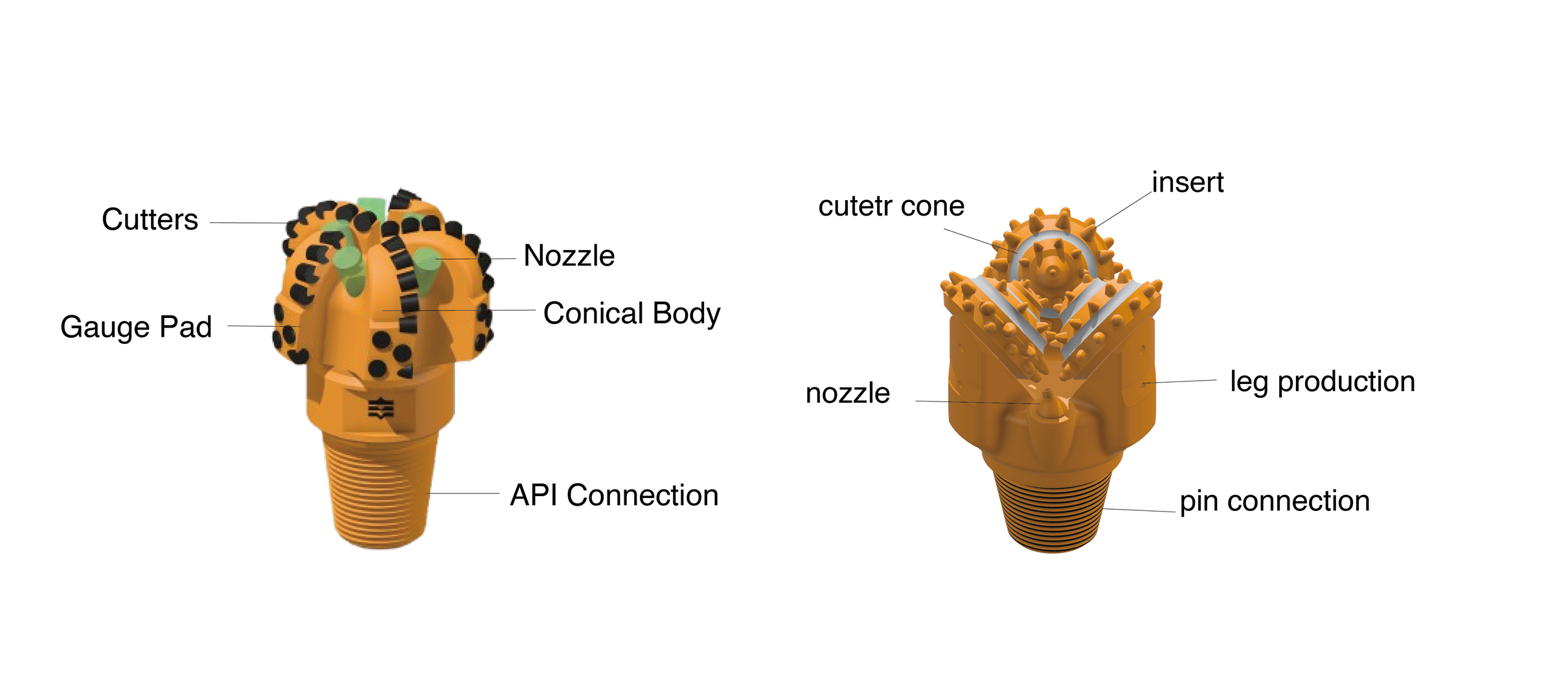

PDC bits use fixed diamond cutters to slice through rock, reducing friction and wear. Tricone bits rely on rotating cones to crush softer formations, balancing cost and performance in less challenging grounds.

Dive deeper: Key Design Comparisons

| Feature | PDC Bit | Tricone Bit |

|---|---|---|

| Cutting Mechanism | Shearing with fixed PDC cutters | Crushing with rotating cones |

| Material | Polycrystalline diamond composite | Tungsten carbide teeth on steel cones |

| Best For | Soft to medium soils (clay, loam) | Hard rock (sandstone, shale) |

| Speed | High RPM with minimal re-entry | Moderate RPM, stable in unstable layers |

| Wear Resistance | Superior (1.5–3x longer lifespan) | Lower (requires frequent replacement) |

PDC bits avoid grinding motions, which reduces heat buildup and bit "balling" in sticky formations. Their streamlined body design allows faster penetration rates. Tricone bits, however, adapt better to mixed layers through adjustable cone rotation speeds. For projects with variable geology, Tricone’s rolling action can handle sudden changes from clay to gravel without stalling.

Why are PDC Bits Gaining Popularity in HDD Operations?

Operators are shifting to PDC for demanding projects. What’s driving this trend? Let’s break it down.

PDC bits dominate in hard rock HDD due to 30–50% faster drilling speeds and 2x longer service life. Their sealed bearing systems also reduce downtime for maintenance.

Dive deeper: Performance Advantages Over Tricone

-

Reduced Torque Fluctuations

PDC’s fixed cutters maintain consistent torque, which protects drill rigs from sudden load changes. Tricone bits often create irregular torque spikes in hard layers, increasing equipment stress. -

Mud Flow Optimization

PDC designs allow larger fluid ports, improving cuttings removal in deep wells. Tricone’s smaller ports can clog in abrasive environments, slowing progress.

Conclusion

No "best" bit exists—choose based on geology, budget, and project scale. Each drill bit has its unique value in the ever-evolving drilling technology

🛠️ Still deciding between a PDC bit and a tricone bit for your HDD project?

At Drillnova, we provide both solutions—PDC bits for faster penetration in soft to medium formations, and tricone bits for versatility across mixed or harder ground. Each bit is engineered for durability, performance, and compatibility with HDD rigs.

👉 View our PDC bits here or explore tricone bits here to find the right tool—or contact us for expert recommendations.