When you’re faced with tricky drilling conditions, choosing the wrong tool can cost time and money. So how do you decide between Bullet Teeth and Roller Bit?

Bullet Teeth are ideal for soft to medium-hard formations(≤80MPa)Bullet Teeth are point-attack cutters ideal for penetration., while Roller Bits are built for harder rock layers(≥100MPa)Roller Bits are rotating cutters that crush and grind hard rock formations. The right choice depends on your project’s formation, machine, and goals and replacement frequency in hard formations.

No two drilling tools work the same, especially when rock formations get complicated. If you’re a project manager or procurement officer in foundation drilling, choosing the right tool is key to keeping your cost under control and your progress on time. Let's take a closer look.

Basic structure and working principle of Bullet Teeth and Roller Bit?

Getting stuck halfway through a borehole is every driller’s nightmare. That’s why you need to understand how your tools really work.

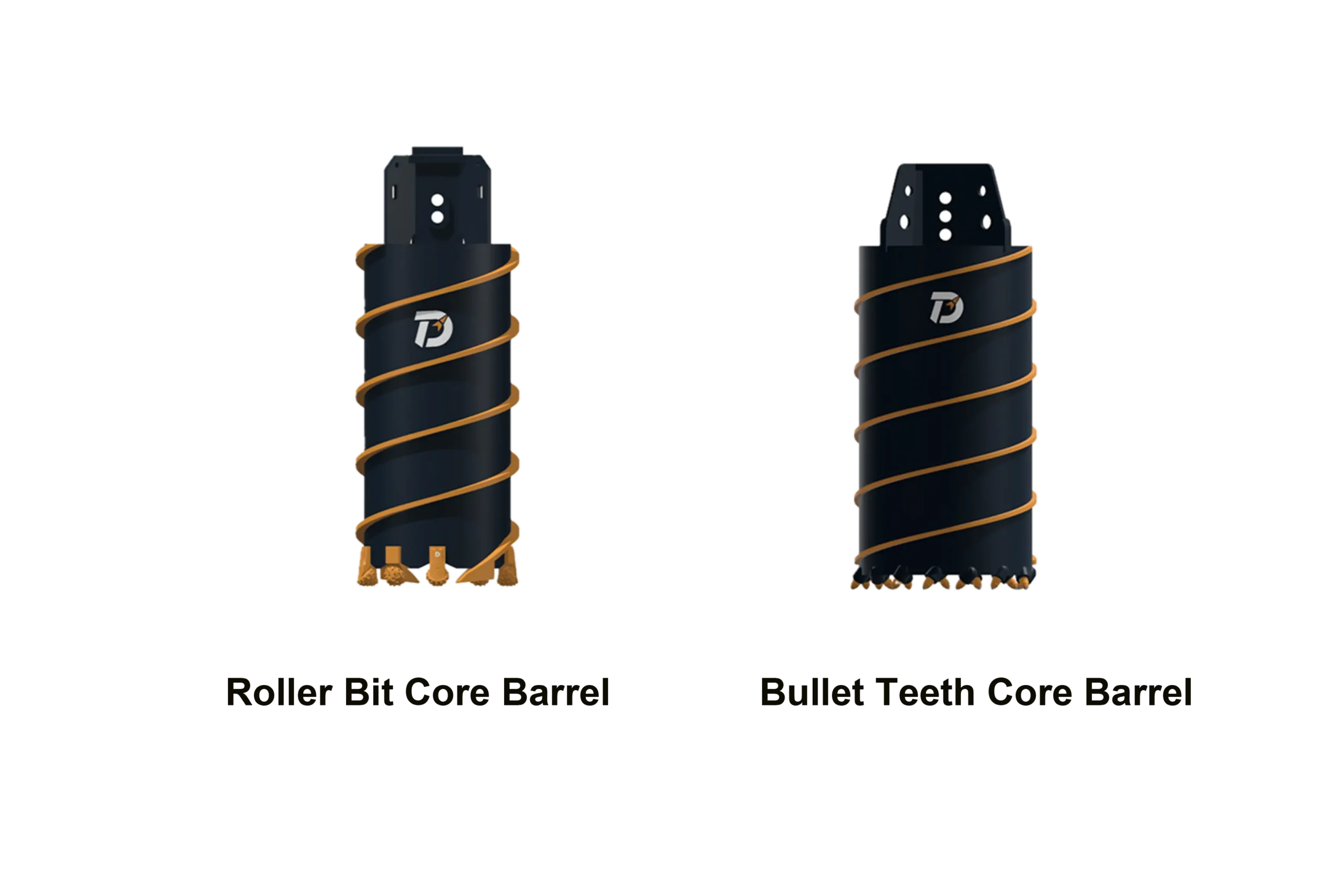

Bullet Teeth are replaceable cutting tools mounted on rotary drilling tools such as augers and core barrels. Roller Bits are rotating cutting heads installed at the bottom of rock barrels, designed to crush rock through rolling and grinding.

How They Work Differently

| Feature | Bullet Teeth | Roller Bit |

|---|---|---|

| Installation Position | Connect via holder station of core barrels or augers | Welded to the bottom of the core barrel |

| Cutting Action | Point-attack, scraping and chipping | Rolling and crushing with tungsten carbide inserts |

| Rotation | Follows barrel rotation | Self-rotating while barrel rotates |

| Maintenance | Easy replacement of individual teeth | bit replacement or bearing maintenance |

Bullet Teeth focus on fast penetration through soft to medium materials. They shear and chip through the soil or rock as the tool rotates. Roller Bits, on the other hand, rotate on their own axis while the barrel turns, effectively crushing the rock using weight and friction. This action makes them more suitable for dense, abrasive formations.

Comparison of applicable formations and engineering scenarios?

Using the wrong bit can turn a job site into a money pit. Matching the tool to the ground conditions matters.

Bullet Teeth work best in soft to medium formations like clay, gravel, and fractured rock. Roller Bits are better for hard and dense formations like granite, basalt, or high-compression limestone.

Formation Suitability and Use Cases

| Formation Type | Recommended Tool | Notes |

|---|---|---|

| Soft clay | Bullet Teeth | Quick penetration, minimal wear |

| Sandy gravel | Bullet Teeth | Watch for wear on carbide tips |

| Weathered rock | Bullet Teeth | Effective but may chip easily |

| Medium-hard limestone | Either, depending on project | Roller Bit preferred for consistent performance |

| Dense granite or basalt | Roller Bit | Better crushing performance, slower but safer |

In real-world projects, we often see that Bullet Teeth-equipped core barrels outperform Roller Bits in mixed ground layers due to faster drilling speeds. However, in full-face hard rock, Roller Bits stay more stable and reduce the chance of tool breakage or deviation.

Analysis of wear and tear and service life?

Changing tools mid-project costs time and money. Knowing which tool lasts longer helps you plan better.

Bullet Teeth wear out faster in hard ground and need regular replacement. Roller Bits have longer life in rock but can suffer bearing failure if overloaded or poorly maintained.

Durability Considerations

| Factor | Bullet Teeth | Roller Bit |

|---|---|---|

| Wear Resistance | Good in soft/medium ground | Excellent in hard rock |

| Maintenance | Frequent, simple | Infrequent, complex |

| Common Failure Mode | Tip wear, shank breakage | Bearing lockup, cone loss |

| Average Service Life | 300–600 meters drilling | 800–1500 meters drilling |

I’ve had customers tell me they kept swapping Bullet Teeth every 1–2 shifts when drilling through layered sandstone and shale. When they switched to Roller Bits in those sections, tool life almost doubled, though the penetration rate slowed. It’s always a trade-off.

Cost-benefit comparison: one-time investment vs. long-term operation?

High upfront cost doesn't always mean high total cost. You need to calculate the full picture.

Bullet Teeth are cheaper to buy and easy to replace, but their shorter lifespan may increase long-term cost. Roller Bits are more expensive initially but reduce downtime and replacement frequency in hard formations.

Cost Breakdown Table

| Item | Bullet Teeth | Roller Bit |

|---|---|---|

| Initial Purchase Cost | Low | High |

| Replacement Frequency | High | Low |

| Labor Time for Replacement | Short | Longer (entire bit) |

| Downtime Risk | Higher in hard rock | Lower in hard rock |

| Total Cost in Soft Ground | More economical | Costly and unnecessary |

| Total Cost in Hard Ground | May increase over time | Cost-effective for long bores |

For example, in one deep pile foundation project in Southeast Asia, a customer started with Bullet Teeth to save budget. But they ended up replacing the teeth so often that their cost per meter was 30% higher than if they had used Roller Bits from the start. In hard rock, you don’t save money by cutting corners.

How to choose the right drilling tool according to the project?

Every project is different. The wrong tool choice can ruin progress and blow the budget.

Choose Bullet Teeth when you need speed in softer soils or mixed ground. Use Roller Bits when you face high-strength rock or need a stable, long-lasting drilling solution.

Selection Guide Based on Project Needs

| Project Type | Recommended Tool | Reason |

|---|---|---|

| City center pile foundation in soft clay | Bullet Teeth | Fast progress, easy replacement |

| Mountain foundation in granite | Roller Bit | High crushing force, less tool failure |

| Bridge pier in variable strata | Mix (Hybrid barrels) | Bullet Teeth outside, Roller Bit center |

| High-volume repetitive drilling | Bullet Teeth | Easier logistics, lower unit cost |

| Deep rock drilling with limited access | Roller Bit | Less maintenance, more reliability |

When I talk with procurement managers from companies, they always ask: “Which tool will give me the lowest cost per finished meter?” That’s the right question. And the answer depends on your formation, rig type, and schedule.

Conclusion

Both Bullet Teeth and Roller Bits have their place. The key is knowing your formation and balancing cost with performance.

🪓 Still not sure whether bullet teeth or roller bits are right for your project?

At Drillnova, we supply both solutions—bullet teeth for rotary drilling buckets and roller bit core barrels for heavy-duty rock penetration. Our experts can help you choose the most efficient tool based on your formation and drilling method.

👉 Explore our bullet teeth or roller bit core barrels to learn more—or contact us for tailored advice.