When your drilling project gets delayed by tool wear, the costs climb fast.

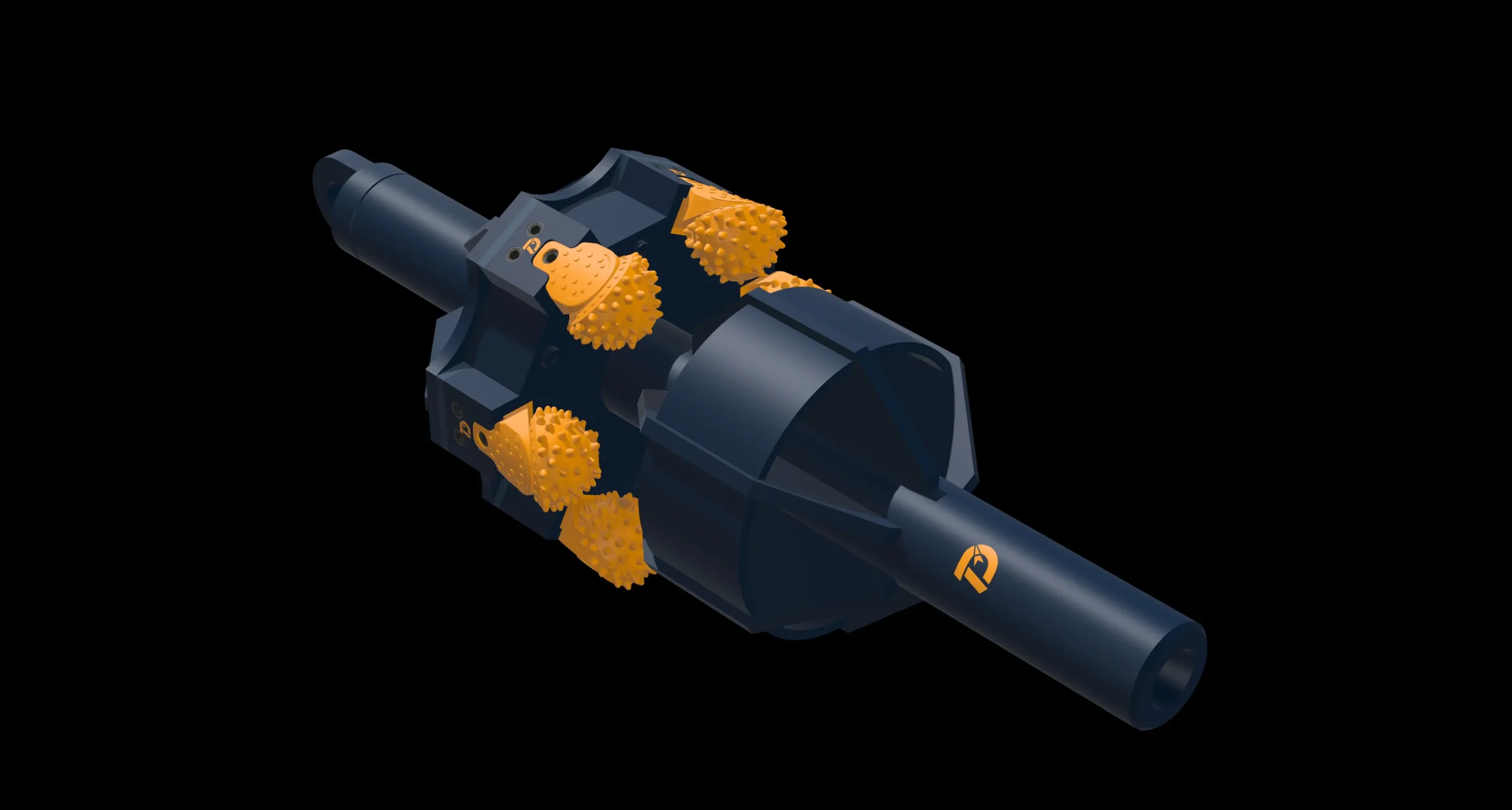

A replaceable hole opener is a trenchless drilling tool with detachable cutter heads, allowing quick replacement without full tool removal, saving time, reducing cost, and increasing flexibility on-site.

Downtime is expensive. Every minute lost in the field pushes up labor costs and delays deadlines. That’s why contractors are looking for tools that can keep up with fast-paced trenchless jobs. Let’s take a closer look at why replaceable hole openers are becoming a smarter choice.

What is a replaceable hole opener?

Worn-out drilling tools used to mean long stops and full tool replacements. That doesn’t work anymore.

A replaceable hole opener is a horizontal directional drilling tool with removable cutter heads that can be quickly swapped out on-site without disassembling the entire body.

How is it different from traditional welded hole openers?

Traditional welded hole openers are made as one unit. Once the cutter is worn out, the entire tool must be taken off, often sent back to the factory or replaced entirely. Replaceable hole openers change this. They use a bolted or clamped structure that holds multiple arms or cutters, which can be changed easily in the field.

| Feature | Welded Hole Opener | Replaceable Hole Opener |

|---|---|---|

| Cutter Replacement | Requires full tool removal | Replace cutter only |

| Maintenance Time | High | Low |

| Cost Efficiency | Lower over time | Higher long-term savings |

| Adaptability | Fixed design | Customizable per job |

This change gives field teams more control and cuts the time needed for tool replacement or upgrade.

How does the replaceable structure work? Why can the cutter head be replaced quickly?

Tool damage can halt your project, especially when drilling in mixed formations. Quick fixes matter.

Replaceable hole openers use a segmented design with bolted arms and cutters that can be changed easily using simple hand tools, even at the job site.

Breaking it down: How does it actually work?

Most designs use a central body that fits various replaceable cutter arms. The arms may hold TCI cutters, PDC cutters, or roller cones. Each is attached using strong bolts or locking mechanisms. When a cutter arm wears out or breaks, the crew removes just that piece and replaces it.

The cutter heads are made in standardized sizes and interfaces. Contractors can stock spares based on soil conditions. With this system, switching from a soft soil cutter to a hard rock cutter is fast. There’s no need to send the whole tool back or wait for new ones to ship.

This flexibility means fewer interruptions and faster decision-making when conditions change.

What trenchless projects are the replaceable hole opener suitable for?

Some tools only work in ideal soil. But that’s not the real world.

Replaceable hole openers are used in HDD projects like fiber optic installations, pipeline crossings, and municipal infrastructure jobs where mixed soil layers are common.

When do I choose this tool?

Replaceable hole openers shine in projects where access is limited or downtime is expensive. For example:

- City road crossings for telecom or electric

- River or railway crossings for oil and gas

- Industrial plant upgrades needing underground pipelines

Their strength is in adapting quickly. If the front layer is clay and the next is cobble or rock, you can change the cutter arms between passes or even during reaming.

This cuts the need for multiple full-size tools and avoids costly transport delays.

Why are more and more contractors choosing replaceable designs?

Projects are getting tighter. Budgets are shrinking. Reliability matters more than ever.

Contractors prefer replaceable hole openers because they reduce downtime, lower maintenance costs, and allow greater flexibility in handling different formations.

What are they telling us?

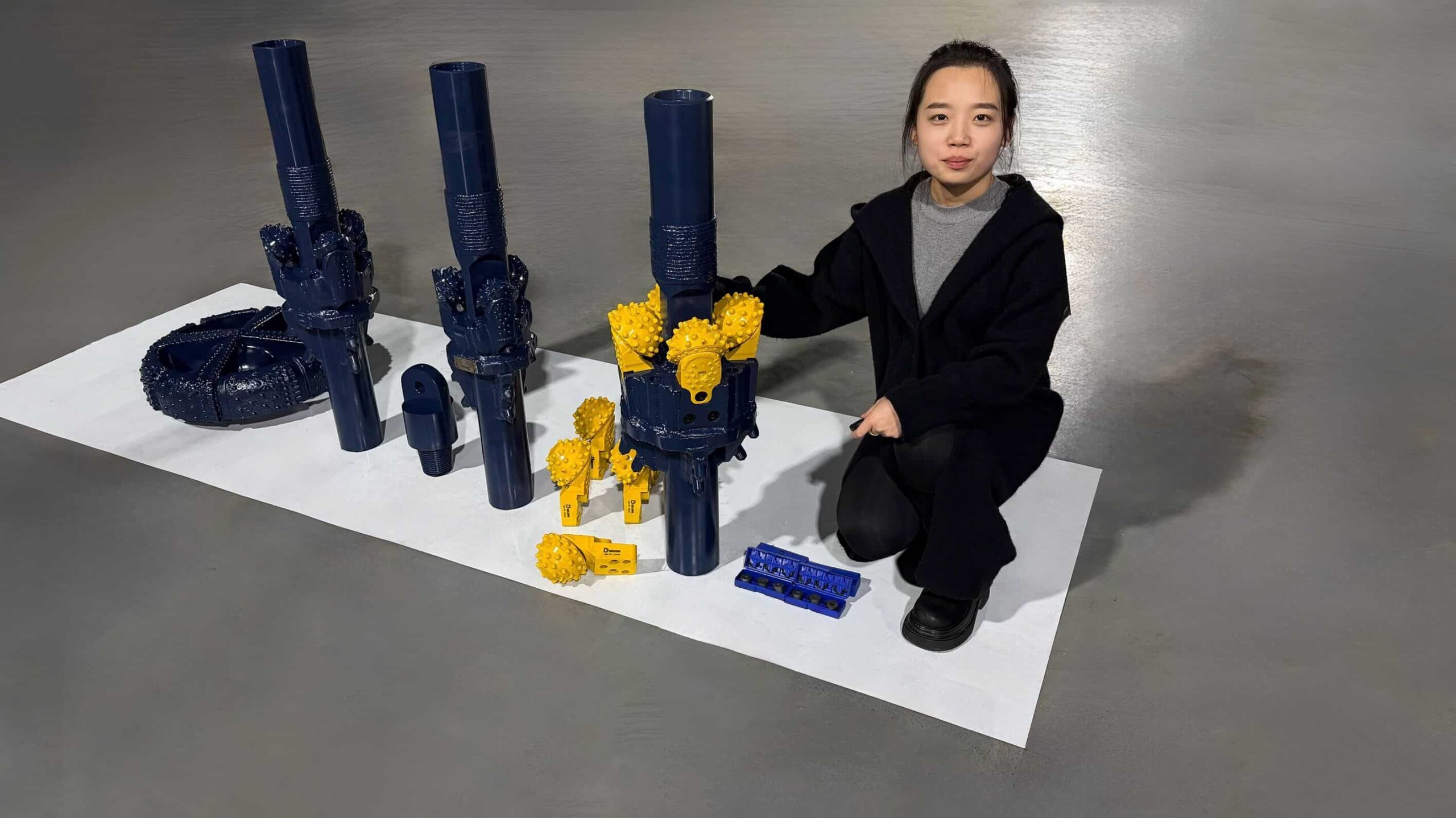

I’ve talked to contractors in North America and Southeast Asia who run multiple HDD projects at once. They say the replaceable design helps them keep one tool body and a few sets of arms in stock. That’s it. No more ordering multiple reamers or overloading their trucks.

They also noted reduced costs over a year. Cutter arms can be purchased individually. That makes budgeting easier. Some even keep spare arms on the rig and change them between jobs without calling a technician.

This trend isn’t just about convenience. It’s about staying competitive in a high-pressure market.

Replaceable hole opener selection guide: What core parameters should buyers pay attention to?

Not all replaceable hole openers are made equal. Buying the wrong one wastes money.

When choosing a replaceable hole opener, check the body size, cutter type, connection size, and formation type to match your project’s drilling conditions.

What should I look at before buying?

Here are the key things I always ask when helping a customer:

| Parameter | What It Affects | How to Choose |

|---|---|---|

| Hole Size | Final bore size | Choose reamer diameter 1.2–1.5x product pipe |

| Cutter Type | Soil/rock compatibility | TCI for hard formations, PDC for soft/abrasive |

| Connection Type | Rig match | Match with HDD rig (e.g., API 2 3/8", 3 1/2" etc.) |

| Replaceable System | Maintenance ease | Choose arms that match your field tools |

| Body Reusability | Cost efficiency | Make sure it’s compatible with future cutter heads |

For customers in Australia or the Middle East, we sometimes customize the connection or arm length to fit their unique conditions.

Ask your supplier for drawings or real photos before confirming. A good supplier will also offer spare arms, bolts, and guidance for installation.

Case sharing: How do Middle Eastern customers improve construction efficiency with a replaceable hole opener?

Hot climates. Harsh ground. Remote sites. Every breakdown is costly.

In Saudi Arabia, one client reduced downtime by over 40% after switching to replaceable hole openers for their HDD pipeline work across rocky desert terrain.

What happened?

One of our customers runs fiber cable under highways in Saudi Arabia. Before using our replaceable hole openers, they had to send back worn reamers every few weeks. Delivery took days. Projects fell behind.

We provided a reamer body with TCI arms and PDC options. The client trained their crew to replace arms in the field. They stocked 10 sets of cutters for different soils. Within one quarter, they cut tool delays by 43%, finished projects faster, and reported fewer tool-related breakdowns.

Their project manager said it gave them more control. They weren’t waiting anymore. They were acting.

This isn’t just about a tool. It’s about staying on top of your job, no matter where it is.

Summary

Replaceable hole openers help contractors save time, reduce cost, and work smarter by allowing on-site cutter changes and adapting to changing formations quickly.

🔩 Interested in upgrading to a replaceable hole opener for your HDD projects?

At Drillnova, we design and manufacture replaceable HDD hole openers with durable arms, easy maintenance, and flexible cutter configurations—perfect for contractors looking to reduce cost and downtime.

👉 Explore our Replaceable Hole Openers here and see how we can support your next drilling challenge.